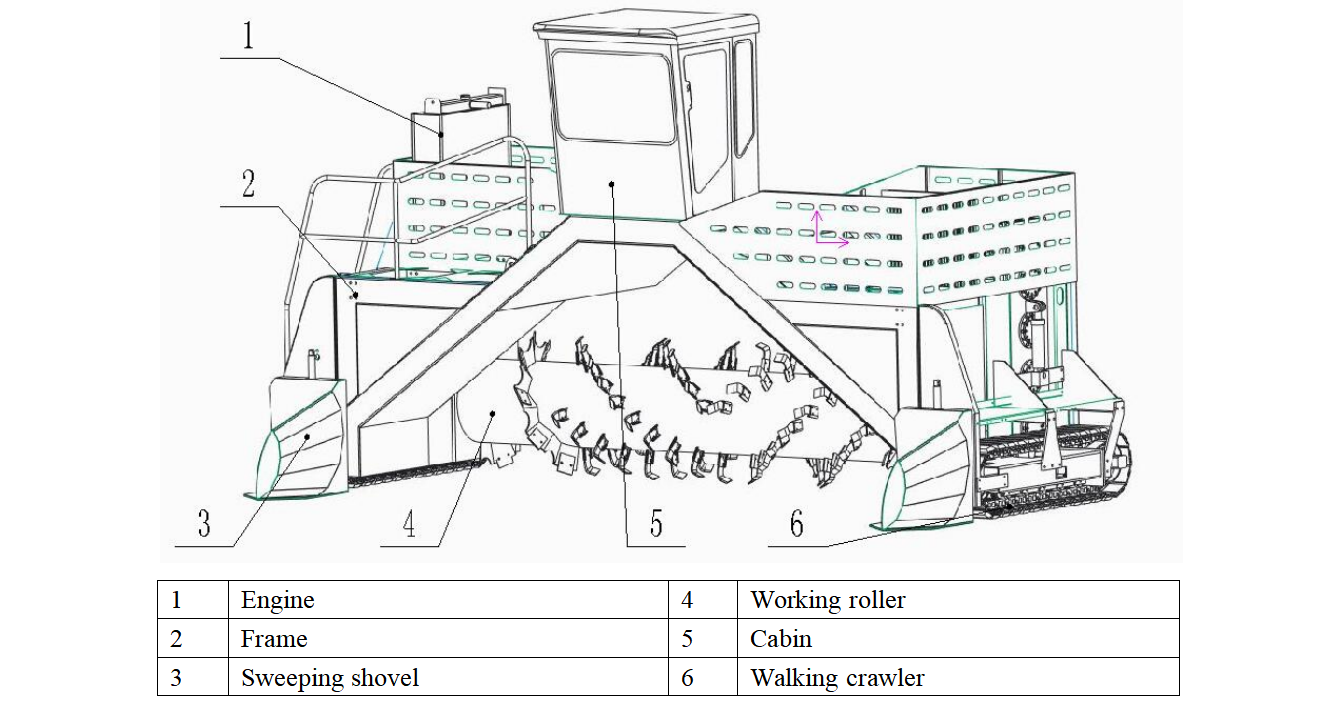

M4800 Crawler Compost Turner

As TAGRM's flagship product to replace the M3800, the M4800 has re-upgraded the power configuration and uses the latest overall lifting technology, so that it still maintains high power output even when the width and height are increased, which improves the processing complexity. material capacity.

Product parameter

| Model | M4800 | Ground clearance | 100mm | H2 | |

| Rate Power | 216KW(293PS) | 6CTA8.3-C260-II | Ground pressure | 0.75Kg/cm² | |

| Rate speed | 2200 r/min | Working width | 4800-5000mm | Max. | |

| Fuel consumption | ≤231g/KW·h | Working height | 2200mm | Max. | |

| Battery | 24V | 2×12V | Pile shape | Triangle | 42° |

| fuel capacity | 200L | Forward speed | L: 0-8m/min H: 0-21m/min | ||

| Crawler tread | 5685mm | W2 | Rear speed | L: 0-8m/min H:0-21m/min | |

| Crawler size | 400mm | Steel with shoe | Feed port width | 4900 | W1 |

| Oversize | 6320×2895×3650mm | W3×L1×H1 | Turning radius | 3200mm | mini |

| Weight | 10000kg | Without fuel | Drive mode | Hydraulic control | |

| Diameter of roller | 1080mm | With knife | Working capacity | 2500m³/h |

Efficient, Energy-saving and Powerful Engine(Cummins)

Professionally adjusted, specially custom, high quality brand turbocharged engine. It has strong power, low fuel consumption and high reliability, and meets the requirements of various complex working conditions of the compost turner.

Hydraulic Control Valve

High-tech content control valve, upgraded and optimized hydraulic system. It has high quality, excellent performance, long service life and low failure rate.

Integrated operation by the single handle.

Specially Designed Roller

Manganese steel cutters on the roller are strong and corrosion resistant. By scientific spiral design, while the machine crushing the raw materials, mixing and turning the raw materials uniformly with one thousandth dispersion, and filling the compost with oxygen and cooling at the same time.

Please choose special rollers and knives according to the different characteristics of raw materials.

Crawler walking system

Steel engineering track + 40mm thick high wear-resistant rubber plate assembly, high strength, strong bearing capacity, long life, single-section replacement, low replacement cost, easy replacement

Engine Parameter

| Brand | CUMMINS | Peak Torque/Speed | 1135/1500N.m/rpm |

| Model | 6CTA8.3-C260-II | Cold Style | Water-cooled |

| Displacement | 8.3L | Emission standard | China stage IIA |

| Cylinder diameter | 114mm | Cylinder No. | 6 |

| Piston stroke | 135mm | Electronic control system | ECM |

| Rate speed | 2200r/min | Fuel | Diesel |

| Roted Power | 194kW | Weight | 637KG |

| Fuel consumption | 231g/Kw.h | Place of Origin | China |

Successful case:

Russia, domestic waste treatment, with an annual processing capacity of 200,000 tons, TAGRM's flagship M4800 turner fully meets the needs of customers in terms of performance, but customers need to install roller-type laminating equipment to achieve the purpose of deodorization and accelerated fermentation. Of course, for us, it's very simple.

The function of the compost turner:

1. Stirring function in raw material conditioning.

In compost production, to adjust the carbon-nitrogen ratio, pH, water content, etc. of raw materials, some auxiliary materials must be added. The main raw materials and various auxiliary materials, which are roughly stacked together in proportion, can be mixed evenly by the turning and polishing machine to achieve the purpose of conditioning.

2. Adjust the temperature of the raw material pile.

During the operation of the compost turning machine, the raw material pellets are fully contacted and mixed with the air, and a large amount of fresh air can be contained in the material pile, which is helpful for aerobic microorganisms to actively generate fermentation heat, and the temperature of the pile rises; when the temperature is high, the supplement of fresh air can be used. Cool down the stack temperature. A state of alternating medium temperature - high temperature - medium temperature - the high temperature is formed, and various beneficial microorganisms grow and multiply rapidly in the temperature range they are adapted to.

3. Improve the permeability of the raw material windrow pile.

The turning system can process the material into small clumps, so that the viscous and dense material pile becomes fluffy and elastic, forming a suitable porosity.

4. Adjust the moisture of the raw material windrow pile.

The suitable water content of raw material fermentation is around 55%, and the moisture standard of finished organic fertilizer is below 20%. During fermentation, biochemical reactions will generate new water, and the consumption of raw materials by microorganisms will also cause water to lose its carrier and become free. Therefore, with the timely reduction of water during the fertilizer-making process, in addition to the evaporation formed by heat conduction, the turning of the raw material by the turning machine will form mandatory water vapor emission.

5. To realize the special requirements of the composting process.

For example, the crushing of raw materials, giving a certain shape to the raw material pile or realizing quantitative displacement of raw materials, etc.

The process of making compost:

1. Livestock and poultry manure and other materials, organic domestic waste, sludge, etc. are used as fertilizer base materials, pay attention to the carbon-nitrogen ratio (C/N): Since composting materials have different C/N ratios, we need to use The C/N ratio is controlled at the 25~35 that the microorganism likes and the fermentation can proceed smoothly. The C/N ratio of the finished compost is usually 15~25.

2. After the C/N ratio is adjusted, it can be mixed and stacked. The trick at this point is to adjust the overall moisture content of the compost to 50-60% before starting. If the water content of livestock and poultry manure and other materials, domestic garbage, sludge, etc. is too high, you can add organic matter, relatively dry auxiliary materials that can absorb water, or use the method of backflow to put the dry fertilizer below to form strips, and put the containing Livestock and poultry manure and other materials, domestic garbage, sludge, etc. with a large amount of water are placed in the middle so that the water above can seep to the bottom and then be turned over.

3. Stack the base material in strips on a flat surface. The stack width and height should be equal to the working width and height of the equipment as much as possible, and the specific length needs to be calculated. TAGRM's turners are equipped with integral hydraulic lifting and drum hydraulic lifting technology, which can adjust themselves to the maximum size of the stack.

4. Sprinkle the fertilizer base materials such as the piled livestock and poultry manure and other materials, domestic garbage, sludge, etc. with biological fermentation inoculants.

5. Use a turning machine to evenly mix the straw, livestock and poultry manure and other organic materials, domestic garbage, sludge, (water content should be 50%-60%), fermentation bacteria agent, etc., and it can be deodorized in 3-5 hours. , 16 hours to heat up to 50 degrees (about 122 degrees Fahrenheit), when the temperature reaches 55 degrees (about 131 degrees Fahrenheit), turn the heap again to add oxygen, and then start stirring whenever the temperature of the material reaches 55 degrees to achieve uniform fermentation, The effect of increasing oxygen and cooling, and then repeat this process until it is completely decomposed.

6. The general fertilization process takes 7-10 days. Due to different climates in different places, it may take 10-15 days for the material to be completely decomposed. high, potassium content increased. Powdered organic fertilizer is made.

Compost turning operation:

1. It can be controlled by both temperature and smell. If the temperature is higher than 70°C (about 158 degrees Fahrenheit), it should be turned over, and if you smell the smell of anaerobic ammonia, it should be turned over.

2. When turning the pile, the inner material should be turned outward, the outer material should be turned inside, the upper material should be turned downward, and the lower material should be turned upward. This ensures that the material is fully and evenly fermented.

Video

M4800 turning the compost material on a plant. M4800 spray system sparying water and ferment to compost.